- Step And Scan Lithography

- Complexity Of Lithography Tools For Sale

- Complexity Of Lithography Tools And Accessories

LithographyLithography is a method of printing an image by applying patterned layers of color to paper with a series of etched metal or stone plates. This is the process used to print many newspapers and multi-colored lithographs. It is also the general name for the techniques used to fabricate integrated circuits (ICs).The concept of lithography was developed by German actor and playwright Johann Alois Senefelder (1771 –1834) between 1796 and 1798, while in (what is now the ). He used a stone slab with printed grease marks and dampened it with water.

When a coating of ink was applied to the stone, it adhered to the grease marks and washed away from the wet areas. The ink was then transferred to paper by pressing the stone against it.Senefelder ’s method was perfected over time.

Metal plates were soon used in place of stone slabs. Several chemical solutions that repelled water and adhered to ink better than grease were later used.

Lithography was used with several different color inks to create color pictures, called lithographs, which were made famous by Currier and Ives.The invention of photography in the twentieth century spurred the development of a new lithographic process called photolithography. In this method, the printer shines a bright light through a photo negative onto a thin plate coated with light-sensitive chemicals. The areas of the plate struck by the light harden into a reproduced image, serving the same function as the grease design in early lithography.

Today, lithographic processes are the most widely-used printing methods.The same lithographic concepts used to reprint text and pictures on paper can be used to manufacture integrated circuits. In this case, a polymer resist is used to repel the subsequently applied layers of metal conductors, semiconductor materials, and dielectric insulators, which are the “ink. ” An is a tiny version of a conventional electrical circuit. Thin films of various materials act as insulators between conductive material and the silicon metal substrate, or protect existing layers from implantation of other atoms. These devices are built by coating a silicon wafer with patterned layers of material, designed to allow the insulators or protective barriers to be applied, or to leave holes in the barrier layer permitting electrical contact. Sophisticated circuits may require 20 or more layers. Small features and narrow lines must be precisely placed, and the absence of material in a given spot is as critical as the presence of it somewhere else.There are several ways lithography is used to make integrated circuits, including visible and ultraviolet lithography (forms of photolithography), electron beam patterning, ion beam patterning, and x-ray lithography.

The most common method is photolithography, which is well suited to high volume production of consumer electronics. Citation stylesEncyclopedia.com gives you the ability to cite reference entries and articles according to common styles from the Modern Language Association (MLA), The Chicago Manual of Style, and the American Psychological Association (APA).Within the “Cite this article” tool, pick a style to see how all available information looks when formatted according to that style. Then, copy and paste the text into your bibliography or works cited list.Because each style has its own formatting nuances that evolve over time and not all information is available for every reference entry or article, Encyclopedia.com cannot guarantee each citation it generates. Therefore, it’s best to use Encyclopedia.com citations as a starting point before checking the style against your school or publication’s requirements and the most-recent information available at these sites. Modern Language AssociationThe Chicago Manual of StyleAmerican Psychological AssociationNotes:.Most online reference entries and articles do not have page numbers. Therefore, that information is unavailable for most Encyclopedia.com content.

However, the date of retrieval is often important. Refer to each style’s convention regarding the best way to format page numbers and retrieval dates.In addition to the MLA, Chicago, and APA styles, your school, university, publication, or institution may have its own requirements for citations.

Therefore, be sure to refer to those guidelines when editing your bibliography or works cited list. LithographyLithography is a method of printing an image by applying patterned layers of color to paper with a series of etched metal or stone plates. This is the process used to print many newspapers and multi-colored lithographs. It is also the general name for the techniques used to fabricate integrated circuits (ICs).Lithography in printingThe concept of lithography was developed by German Aloys Senefelder in 1796.

He used a stone slab with printed grease marks and dampened it with water. When a coating of ink was applied to the stone, it adhered to the grease marks and washed away from the wet areas. The ink was then transferred to paper by pressing the stone against it.Senefelder's method was perfected over time. Metal plates were soon used in place of stone slabs. Several chemical solutions that repelled water and adhered to ink better than grease could were experimented with. Lithography was used with several different color inks to create color pictures, called lithographs, which were made famous by Currier and Ives.PhotolithographyThe invention of photography in the twentieth century spurred the development of a new lithographic process called photolithography. In this method, the printer shines a bright light through a photo negative onto a thin plate coated with light-sensitive chemicals.

The areas of the plate struck by the light harden into a reproduced image, serving the same function as the grease design in early lithography. Today, lithographic processes are the most widely-used printing methods.Lithography and integrated circuitsThe same lithographic concepts used to reprint text and pictures on paper can be used to manufacture integrated circuits.

In this case, a polymer resist is used to repel the subsequently applied layers of metal conductors, semiconductor materials, and dielectric insulators which are the 'ink.' An is a tiny version of a conventional electrical circuit. Thin films of various materials act as insulators between conductive material and the silicon metal substrate, or protect existing layers from implantation of other atoms. These devices are built by coating a silicon wafer with patterned layers of material, designed to allow the insulators or protective barriers to be applied, or to leave holes in the barrier layer permitting electrical contact. Sophisticated circuits may require 20 or more layers. Small features and narrow lines must be precisely placed, and the absence of material in a given spot is as critical as the presence of it somewhere else.There are several ways lithography is used to make integrated circuits, including visible and ultraviolet lithography (forms of photolithography), electron beam patterning, ion beam patterning, and x-ray lithography. The most common method is photolithography, which is well suited to high volume production of consumer electronics.Making integrated circuitsIn the manufacture of integrated circuits, the silicon wafer that acts as the base and a light-sensitive polymer material, called photoresist, are used to create the pattern of the circuit's layers.

Negative photoresists harden when exposed to light, adhering to the base through the developing process. Positive photoresists degrade when they are exposed to light and developed, leaving a depression. The coated wafer is then dried 10-30 minutes in an oven at 176–194°F (80–90°C).After photoresist is applied to the silicon wafer, it is selectively exposed to light with the aid of a reticle. A reticle consists of a layer of patterned chrome on transparent glass; gaps in the chrome permit light to reach the resist-covered wafer.

Exposure takes place in a device, called a stepper, that shines light on the wafer through the transparent regions of the reticle. Only a small region of the wafer is exposed at a time.

Then the wafer is moved, or stepped, forward and a new segment is exposed. After exposure, the wafer is put into developing solution where the positive and unexposed photoresists are removed. It is hard-baked at temperatures between 248–356°F (120–180°C).After the photoresist is in place, a layer of conducting, semiconducting, or insulating metal solution is applied to the wafer and adheres in the pattern opposite to the photoresist. The application and removal of photoresist and metal solutions is repeated 10-20 times in the manufacture of a single. In addition to the number of steps needed to make the circuit, the complexity of the task is increased by the necessity for precision in the manufacturing process.

For instance, some circuits use printed features as small as 0.35 micron. A human hair, on the other hand, is about 100 microns in diameter. Resources booksGlendinning, William, and John Helbert, eds. Handbook of VLSI Microlithography. Park Ridge, NJ: Noyes Publications, 1991.Jaeger, Richard. Introduction to Microelectronic Fabrication., NY: Addison-Wesley, 1988.Kristin Lewotsky KEY TERMS. Negative photoresist—A type of photosensitve polymer that leaves a barrier only where exposed to light.

Photolithography—A method of integrated circuit fabrication that uses a light-sensitive polymer to pattern a silicon wafer with other materials. Photoresist—Photosensitive polymer that is used to pattern silicon wafers during integrated circuit fabrication. Positive photoresist—A type of photosensitive polymer that leaves a barrier only where not exposed to light. Reticle—A photomask used to print patterns on silicon wafers, typically made of chrome-patterned transparent glass. Stepper—A lithographic system that exposes the wafer one small section at a time before 'stepping' to the next location. Substrate—The foundation material on which integrated circuits are built; usually made of silicon.

Wafer—A very thin disk of silicon metal on which integrated circuits are built. Citation stylesEncyclopedia.com gives you the ability to cite reference entries and articles according to common styles from the Modern Language Association (MLA), The Chicago Manual of Style, and the American Psychological Association (APA).Within the “Cite this article” tool, pick a style to see how all available information looks when formatted according to that style. Then, copy and paste the text into your bibliography or works cited list.Because each style has its own formatting nuances that evolve over time and not all information is available for every reference entry or article, Encyclopedia.com cannot guarantee each citation it generates. Therefore, it’s best to use Encyclopedia.com citations as a starting point before checking the style against your school or publication’s requirements and the most-recent information available at these sites. Modern Language AssociationThe Chicago Manual of StyleAmerican Psychological AssociationNotes:.Most online reference entries and articles do not have page numbers. Therefore, that information is unavailable for most Encyclopedia.com content. However, the date of retrieval is often important.

Refer to each style’s convention regarding the best way to format page numbers and retrieval dates.In addition to the MLA, Chicago, and APA styles, your school, university, publication, or institution may have its own requirements for citations. Therefore, be sure to refer to those guidelines when editing your bibliography or works cited list. LithographyScientific Process. The technology involved in lithography was developed by a Bavarian named Alois Senefelder in 1795. It spread to in 1816 and by 1822 was being used in London.

In the, Bass Otis, a student of the great portrait painter, began to experiment with the new techniques sometime around 1819. Lithography was a delicate technique that required a particular kind of stone, imported from, on which the artist drew using special crayons. When the design was finished, the stone would be bathed in gum and acids which would harden the crayondesign and cause it to stand out in relief, turning the stone into a plate that, when wet and inked, could be pressed onto paper to make a print.Publishing. Before lithography was introduced, pictures in books and magazines were reproduced from copperplate engravings or from woodcuts, which were slow and difficult processes. Lithography made book and magazine illustration easier and less expensive. More and more, authors were able to add illustrations to their books, a step that subtly altered how literature was received. Magazine editors were able to vary the visual appeal of their products so that Godey ’s Lady ’s Book, for example, could draw on lithographic technology to print fashion plates and other illustrated material for its readers.

Sheet-music publishers also capitalized on the, packaging songs with illustrations that suggested their contents.Currier and Ives. Nathaniel Currier got his start in 1828 as apprentice to William and John Pendleton of Boston, the first American company to make lithography a commercial success. Eventually Currier settled in and established his own business at 1 in 1835.

Currier ’s company, later known as Currier and Ives after James M. Ives, a skilled business manager and self-educated artist, joined the firm in 1852, billed itself as offering “Colored Engravings for the People.

” Over the years Currier and Ives offered a wide range of prints; today the collection of known Currier and Ives prints totals over seven thousand illustrations. Prints included views of city and country locations; political cartoons and banners; portraits of American and European celebrities and political figures; illustrations of historical events; blank certificates for birth, marriage, church membership, or death; country and pioneer home scenes; sheet music; nature scenes; and pictures of trains, horses (a Currier and Ives specialty), and sporting events. To produce this enormous range of illustrations, produced at a rate of three per week, Currier and Ives relied on various artists. The company regularly bought drawings as they were offered, hired artists as full-time staff members, and, on occasion, hired independent lithographers.Art for the Masses.

Step And Scan Lithography

Lithographic prints produced by Currier and Ives and other lithographers were an important way of disseminating art to the American public. The many Americans unable to afford original art could own reproductions produced and distributed by lithographers, a development that some criticized as a devaluation of art itself. The drawing involved in lithography also provided jobs for would-be artists to supplement the portrait painting or teaching that artists typically did in order to support their more-idealistic endeavors. Ironically, while the mass production of art threatened to outdo or overshadow the ideal of individual artistic production, at the same time it provided artists with the means they needed to earn a living while they worked on more-ambitious individual projects.Harry T. Peters, Currier & Ives: Printmakers to the People (Garden City, N.Y.: Doubleday, 1942);John W.

Reps, Views and Viewmakers of Urban America: Lithographs of Towns and Cities in the and, Notes on the Artists and Publishers, and a Union Catalog of Their Work, 1825 –1925 (Columbia: University of Missouri Press, 1984). Citation stylesEncyclopedia.com gives you the ability to cite reference entries and articles according to common styles from the Modern Language Association (MLA), The Chicago Manual of Style, and the American Psychological Association (APA).Within the “Cite this article” tool, pick a style to see how all available information looks when formatted according to that style. Then, copy and paste the text into your bibliography or works cited list.Because each style has its own formatting nuances that evolve over time and not all information is available for every reference entry or article, Encyclopedia.com cannot guarantee each citation it generates. Therefore, it’s best to use Encyclopedia.com citations as a starting point before checking the style against your school or publication’s requirements and the most-recent information available at these sites. Modern Language AssociationThe Chicago Manual of StyleAmerican Psychological AssociationNotes:.Most online reference entries and articles do not have page numbers.

Therefore, that information is unavailable for most Encyclopedia.com content. However, the date of retrieval is often important. Refer to each style’s convention regarding the best way to format page numbers and retrieval dates.In addition to the MLA, Chicago, and APA styles, your school, university, publication, or institution may have its own requirements for citations. Therefore, be sure to refer to those guidelines when editing your bibliography or works cited list. Lithography (lĬthŏg´rəfē), type of planographic or surface printing.

It is distinguished from letterpress (relief) printing and from intaglio printing (in which the design is cut or etched into the plate). Lithography is used both as an art process and as a commercial process. In commercial printing the term is used synonymously with offset printing.The ProcessAll planographic printing is based on chemical action, and lithography is based on the mutual antipathy of oil and water.

As the name Gr.,=writing on stone implies, a lithograph is printed from a stone (except in commercial processes, where grained metal or plastic plates are employed). The process was invented c.1796 by the playwright Aloys, and the Bavarian limestone that he employed is still considered the best material for art lithography.The slab of stone is ground to a level surface, which may be of coarse or fine texture as desired. The drawing is made in reverse directly on the stone with a lithographic crayon or ink that contains soap or grease. The fatty acid of this material interacts with the lime of the stone to form an insoluble lime soap on the surface, which will accept the greasy printing ink and reject water.

Accordingly, those parts of the stone that have been drawn upon have an affinity for ink.Sometimes the drawing is made on paper and transferred to a heated stone by pressure. This is known as a transfer lithograph and does not require the artist to reverse his or her drawing. Next, the surface of the stone untouched by grease is desensitized to it, and the portions drawn upon are fixed against spreading by treatment with a and solution. The grease has now penetrated the stone, and the drawing is washed off with turpentine and water. The stone is ready to be inked with a roller and printed, but it must be kept moist. The printing requires a special lithographic press with a sliding bed passing under a scraper.ApplicationsAs a printing process lithography is probably the most unrestricted.

It produces tones ranging from intense black to the most delicate gray as well as a full range of colors. It also simulates with equal facility the effects of pencil, pen, crayon, or brush drawing.

White lines are readily produced by scratching through the drawing on the stone. Several hundred fine proofs can be taken from a stone. The medium was exploited by many artists in the 19th cent., including Goya, Delacroix, Daumier, Gavarni, Manet, Degas, Bonnard, Whistler, and Toulouse-Lautrec, whose are among the most celebrated lithographic masterworks. Davies, George Bellows, Joseph Pennell, and Currier and Ives are among the many artists noted for their lithographs.For the commercial reproduction of art works, photolithography has played an increasingly important role.

In this process a photographic negative is exposed to light over a gelatin-covered paper. Wherever the light does not strike the gelatin, the latter remains soluble while the other parts are rendered insoluble. When the soluble portions are washed away, the pattern to be printed can be inked and transferred to the stone or plate. Color lithography and color photolithography require as many stones or plates as the number of colors employed. The commercial printing applications of the lithographic process are vast in scope and almost unlimited in number.BibliographySee J. Pennell and E.

Pennell, Lithographs and Lithographers (1915); V. Strauss, Lithographers Manual (2 vol. Weber, A History of Lithography (1966); F. Man, Artists' Lithographs: A World History (1970). Citation stylesEncyclopedia.com gives you the ability to cite reference entries and articles according to common styles from the Modern Language Association (MLA), The Chicago Manual of Style, and the American Psychological Association (APA).Within the “Cite this article” tool, pick a style to see how all available information looks when formatted according to that style. Then, copy and paste the text into your bibliography or works cited list.Because each style has its own formatting nuances that evolve over time and not all information is available for every reference entry or article, Encyclopedia.com cannot guarantee each citation it generates. Therefore, it’s best to use Encyclopedia.com citations as a starting point before checking the style against your school or publication’s requirements and the most-recent information available at these sites.

Modern Language AssociationThe Chicago Manual of StyleAmerican Psychological AssociationNotes:.Most online reference entries and articles do not have page numbers. Therefore, that information is unavailable for most Encyclopedia.com content. However, the date of retrieval is often important. Refer to each style’s convention regarding the best way to format page numbers and retrieval dates.In addition to the MLA, Chicago, and APA styles, your school, university, publication, or institution may have its own requirements for citations.

Therefore, be sure to refer to those guidelines when editing your bibliography or works cited list. Citation stylesEncyclopedia.com gives you the ability to cite reference entries and articles according to common styles from the Modern Language Association (MLA), The Chicago Manual of Style, and the American Psychological Association (APA).Within the “Cite this article” tool, pick a style to see how all available information looks when formatted according to that style. Then, copy and paste the text into your bibliography or works cited list.Because each style has its own formatting nuances that evolve over time and not all information is available for every reference entry or article, Encyclopedia.com cannot guarantee each citation it generates. Therefore, it’s best to use Encyclopedia.com citations as a starting point before checking the style against your school or publication’s requirements and the most-recent information available at these sites. Modern Language AssociationThe Chicago Manual of StyleAmerican Psychological AssociationNotes:.Most online reference entries and articles do not have page numbers. Therefore, that information is unavailable for most Encyclopedia.com content. However, the date of retrieval is often important.

Refer to each style’s convention regarding the best way to format page numbers and retrieval dates.In addition to the MLA, Chicago, and APA styles, your school, university, publication, or institution may have its own requirements for citations. Therefore, be sure to refer to those guidelines when editing your bibliography or works cited list.

Citation stylesEncyclopedia.com gives you the ability to cite reference entries and articles according to common styles from the Modern Language Association (MLA), The Chicago Manual of Style, and the American Psychological Association (APA).Within the “Cite this article” tool, pick a style to see how all available information looks when formatted according to that style. Then, copy and paste the text into your bibliography or works cited list.Because each style has its own formatting nuances that evolve over time and not all information is available for every reference entry or article, Encyclopedia.com cannot guarantee each citation it generates. Therefore, it’s best to use Encyclopedia.com citations as a starting point before checking the style against your school or publication’s requirements and the most-recent information available at these sites. Modern Language AssociationThe Chicago Manual of StyleAmerican Psychological AssociationNotes:.Most online reference entries and articles do not have page numbers. Therefore, that information is unavailable for most Encyclopedia.com content. However, the date of retrieval is often important.

Refer to each style’s convention regarding the best way to format page numbers and retrieval dates.In addition to the MLA, Chicago, and APA styles, your school, university, publication, or institution may have its own requirements for citations. Therefore, be sure to refer to those guidelines when editing your bibliography or works cited list. Citation stylesEncyclopedia.com gives you the ability to cite reference entries and articles according to common styles from the Modern Language Association (MLA), The Chicago Manual of Style, and the American Psychological Association (APA).Within the “Cite this article” tool, pick a style to see how all available information looks when formatted according to that style. Then, copy and paste the text into your bibliography or works cited list.Because each style has its own formatting nuances that evolve over time and not all information is available for every reference entry or article, Encyclopedia.com cannot guarantee each citation it generates.

Therefore, it’s best to use Encyclopedia.com citations as a starting point before checking the style against your school or publication’s requirements and the most-recent information available at these sites. Modern Language AssociationThe Chicago Manual of StyleAmerican Psychological AssociationNotes:.Most online reference entries and articles do not have page numbers. Therefore, that information is unavailable for most Encyclopedia.com content. However, the date of retrieval is often important. Refer to each style’s convention regarding the best way to format page numbers and retrieval dates.In addition to the MLA, Chicago, and APA styles, your school, university, publication, or institution may have its own requirements for citations.

Therefore, be sure to refer to those guidelines when editing your bibliography or works cited list. Citation stylesEncyclopedia.com gives you the ability to cite reference entries and articles according to common styles from the Modern Language Association (MLA), The Chicago Manual of Style, and the American Psychological Association (APA).Within the “Cite this article” tool, pick a style to see how all available information looks when formatted according to that style. Then, copy and paste the text into your bibliography or works cited list.Because each style has its own formatting nuances that evolve over time and not all information is available for every reference entry or article, Encyclopedia.com cannot guarantee each citation it generates. Therefore, it’s best to use Encyclopedia.com citations as a starting point before checking the style against your school or publication’s requirements and the most-recent information available at these sites. Modern Language AssociationThe Chicago Manual of StyleAmerican Psychological AssociationNotes:.Most online reference entries and articles do not have page numbers. Therefore, that information is unavailable for most Encyclopedia.com content.

However, the date of retrieval is often important. Refer to each style’s convention regarding the best way to format page numbers and retrieval dates.In addition to the MLA, Chicago, and APA styles, your school, university, publication, or institution may have its own requirements for citations.

Therefore, be sure to refer to those guidelines when editing your bibliography or works cited list. Citation stylesEncyclopedia.com gives you the ability to cite reference entries and articles according to common styles from the Modern Language Association (MLA), The Chicago Manual of Style, and the American Psychological Association (APA).Within the “Cite this article” tool, pick a style to see how all available information looks when formatted according to that style. Then, copy and paste the text into your bibliography or works cited list.Because each style has its own formatting nuances that evolve over time and not all information is available for every reference entry or article, Encyclopedia.com cannot guarantee each citation it generates. Therefore, it’s best to use Encyclopedia.com citations as a starting point before checking the style against your school or publication’s requirements and the most-recent information available at these sites. Modern Language AssociationThe Chicago Manual of StyleAmerican Psychological AssociationNotes:.Most online reference entries and articles do not have page numbers. Therefore, that information is unavailable for most Encyclopedia.com content. However, the date of retrieval is often important.

Refer to each style’s convention regarding the best way to format page numbers and retrieval dates.In addition to the MLA, Chicago, and APA styles, your school, university, publication, or institution may have its own requirements for citations. Therefore, be sure to refer to those guidelines when editing your bibliography or works cited list.

Citation stylesEncyclopedia.com gives you the ability to cite reference entries and articles according to common styles from the Modern Language Association (MLA), The Chicago Manual of Style, and the American Psychological Association (APA).Within the “Cite this article” tool, pick a style to see how all available information looks when formatted according to that style. Then, copy and paste the text into your bibliography or works cited list.Because each style has its own formatting nuances that evolve over time and not all information is available for every reference entry or article, Encyclopedia.com cannot guarantee each citation it generates. Therefore, it’s best to use Encyclopedia.com citations as a starting point before checking the style against your school or publication’s requirements and the most-recent information available at these sites. Modern Language AssociationThe Chicago Manual of StyleAmerican Psychological AssociationNotes:.Most online reference entries and articles do not have page numbers.

Therefore, that information is unavailable for most Encyclopedia.com content. However, the date of retrieval is often important. Refer to each style’s convention regarding the best way to format page numbers and retrieval dates.In addition to the MLA, Chicago, and APA styles, your school, university, publication, or institution may have its own requirements for citations. Therefore, be sure to refer to those guidelines when editing your bibliography or works cited list.

After three decades of development, a new generation of lithography machines has now been shipped to large computer chip makers. It uses at a wavelength of 13.5 nm to make silicon features down to a few nanometers in size on the memory chips and processors of tomorrow.With more than 100,000 components, such an EUV lithography system is one of the most complex machines ever built. It is pumped by the most powerful laser system ever made in serial production.

In total, it weighs 180 tons and consumes more than 1 MW electrical power. It costs $120 million and is sold out for years.The big foundries have been waiting for it for quite some time. Now, major technical issues are solved thanks to a unique alliance between high-tech companies including Trumpf (Ditzingen, Germany), Zeiss (Oberkochen, Germany), and (Veldhoven, Netherlands). It is worthwhile to take a look at the history of this technological masterpiece, and also to think about what might come next.Why EUV?Extreme ultraviolet (sometimes also called XUV) denotes soft x-rays with wavelengths between 124 and 10 nm or photon energies between 10 eV and 124 eV. The sun produces EUV; humans create it through synchrotrons, or from plasma.Up until now, chip makers have used ultraviolet (laser) light to project complex patterns onto silicon wafers coated with photoresist.

In a process analogous to the development of the old paper photos, these patterns are developed and become conducting or isolating structures within one layer. This process is repeated until the complex systems forming an integrated circuit such as a microprocessor are complete.The development of such lithographic systems is driven by economy: Ever more computing power and storage capacity is needed while costs and power consumption must be lowered. This development can be described in a simple rule, well-known as Moore’s law, which says that the number of transistors in a dense integrated circuit doubles about every two years.A major limitation comes from the laws of optics. German physicist Ernst Abbe found that the resolution of a microscope d is (roughly) limited to the wavelength λ of the light used in illumination. CD = k λ/NA (2)This formula, which governs all lithographic imaging processes, makes obvious why the wavelength is such a crucial parameter.

As a result, engineers have been looking for light sources with ever-shorter wavelengths to produce ever-smaller features. Beginning with UV mercury-vapor lamps, they moved to excimer lasers with a wavelength of 193 nm. The lithography industry received a surprise when that it would drop the 157 nm excimer laser as a next step and instead go for EUV at a 13.5 nm wavelength.

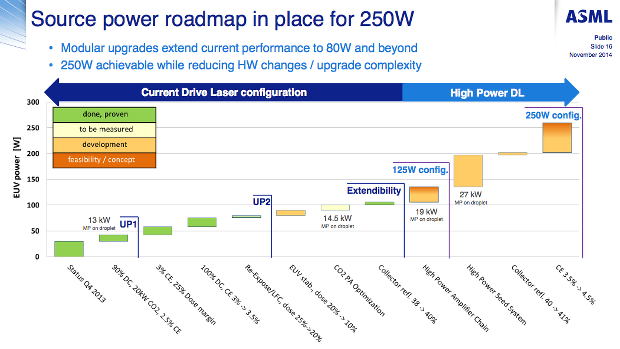

Problems with optical materials were seen as the major obstacle, and EUV seemed just a few development steps away.It was reported at that time that Intel Fellow and director of the company's lithography capital equipment operations, Peter Silverman, presented a. That turned out to be by far too optimistic, and people had to find ways to exploit the 193 nm sources to achieve ever-smaller features through techniques such as and sophisticated illumination tricks.An EUV light source for industry; first of all, a powerful light source was needed. In the early 2000s, discharge-plasma-based sources (such as touted by ) appeared most favorable, but before long laser-produced plasma sources showed that they were most viable for upscaling. Groups in Japan, Europe, and the USA worked hard on this approach.Finally, the San Diego based company Cymer won the race with a system that uses a CO 2 laser to create EUV radiation from a 30 µm droplet of tin. While they, it was 2014 when they, a number that was regarded as the breakthrough for high-volume production. Was a wonderful piece of applied research that made EUV lithography viable after all. To enable faster progress (and to secure its sole supplier), ASML purchased Cymer in 2012.The eventual solution for making just enough EUV radiation for commercial viability is a machine that impresses even seasoned laser experts.

It is based on the most powerful laser that was ever built in serial production: a 40 kW CO 2 laser. The whole system needs a 1 MW power supply. As only the tiny fraction of 200 W of power is used for processing the wafer, cooling is a major issue.The sole supplier of this technology is TRUMPF in Ditzingen, Germany. Trumpf owner and CTO Peter Leibinger is well aware of his company’s role: “If we fail, Moore's law will discontinue. Of course, the world doesn't depend on TRUMPF, but without TRUMPF, the chip industry couldn't do it,” he said in an.Typical CO 2 lasers from TRUMPF deliver some kilowatts of continuous-wave (CW) radiation.

This is just right for cutting steel. For EUV, TRUMPF developed a laser that produces 40 kW of pulsed radiation at a repetition rate of 50 kHz. The laser, with its two seeders and four amplification stages, is so large that it has to be placed on a separate floor below the EUV machine.To keep pace with the market demand, with 10 production bays just for these lasers. With 10 weeks to put them together, the company now has a capacity of 50 systems per year. At the time of writing, 44 systems were in the field with a total of 30 shipments expected in 2019.Peter Leibinger, CTO of TRUMPF, shows the 40 kW CO2 laser that pumps the EUV generator. TRUMPFThe machine has a heart of glassWhile the pump laser is a truly unique machine, the optics within the EUV lithography system are no less challenging. First, the plasma radiation from the tiny tin droplet has to be collected with a huge mirror.

A cites Anthony Yen, ASML’s VP and Head of Technology Development Centers Worldwide, who unveiled a number of interesting details on this part of the machine. With a diameter of 650 mm, the EUV collector has a collection solid angle of 5 sr.

The average reflectivity at 13.5 nm is higher than 40%.According to the report, the reflectivity degrades linearly with time: “With their current customer installed NXE:3400B systems, Yen is reporting a degradation rate of around 0.15% per giga-pulse. ASML would like to get it down to less than 0.1%/GP at the same power (250 W).” In other words, the power drops about 50% in 90 days. Exchanging the collector takes about a day, ASML intends to reduce that towards less than 8 hours with their next-generation NXE:3400. The final goal is 95% availability, which is where all DUV machines are today, the report says.Once the precious EUV light has left the collector, it is further formed and projected by a set of ultraprecise mirrors. The, which is equivalent to the diameter of a hydrogen atom. The optical system is made by another German champion: Zeiss. Carl Zeiss Semiconductor Manufacturing Technology (Zeiss SMT) is the third in the partnership that builds these unique high-tech machines.Note - The resolution of the NXE:3400 systems is about 13 nm; this refers to formula (2) and the actual gate pitch.

This is very different from the 'nodes' often discussed the chip manufacturers. Originally, the nodes referred to the gate length of a transistor. Obviously, this can differ as a function of the process and, hence, of the manufacturer. Today, however, the node only refers to a certain process developed by a chip maker and does not correspond directly to the resolution of the optics. For excample, chip makers tout 7 nm or 3 nm nodes referring to their proprietary processes using similar EUV machines.Inside NXE:3400 – the full optical light path with the EUV source at bottom right and the mask at top. ASMLCooperation is the keyWhile more than 1000 suppliers are involved overall, the core technology is made by Trumpf, Zeiss, and ASML. They developed rather unconventional forms of cooperation in the EUV project.

Peter Leibinger from Trumpf called it a “virtually merged company” with an open-book policy and an extensive exchange of people and knowhow., as the company produced its first lithography optics for Philips in 1983; that business was spun off in 1984 and named ASML.Together, Zeiss and ASML conquered the market for lithography systems well before EUV. In 2010, they already had about 75% market share for lithography systems. So far, they are the sole providers of industry-grade EUV systems. To foster the relation, ASML bought a 24.9% stake in Zeiss SMT for roughly one billion Euros in November 2016. Additionally, with 220 million Euros plus some investments support of 540 million Euros.That money was much needed, as Zeiss was investing heavily in EUV. The company erected halls for manufacturing and metrology near Oberkochen, Germany; currently, it is completing preparation for the next generation of EUV optics with higher NA - another 700 million Euro investment. This includes high-vacuum chambers the size of a truck for metrology of the optical systems.

The mirror surfaces that are tested in these chambers have a maximum tolerance of 0.5 nm, so they use the most precise alignment and metrology technology ever built in industry.Final assembly of a 180 ton toolZeiss SMT has a giant high-tech facility, but it is topped in size by the manufacturing halls at the Veldhoven facilities of ASML. If you go there into the cafeteria, you may feel like you are on a campus in California. Many young people of all nations gather around and sip their lattes. This environment might reflect the fact that ASML has had to rapidly hire new staff to keep pace with their fast growth. In 2018 their staff grew 21%, now employing more than 800 PhDs and more than 7500 engineers in a total workforce of 23,000.The buildings behind the cafeteria comprise the biggest cleanroom facility I have ever seen.

In five by five halls, the EUV steppers machines are completed. The current top model, the NXE:3400B, weighs 180 tons and needs 20 trucks or three fully loaded Boeing 747s for shipment. The price tag is $120 million. It can process 125 wafers per hour with a resolution down to 13 nm.In the second half of 2019, the shipment of an upgraded NXE:3400C was announced.

It will feature higher-transmission optical elements, a modular vessel for significantly faster serviceability, and a faster reticle and wafer handler to support increased productivity. These devices achieve 170 wafers per hour throughput.ASML employees work on the final assembly of an NXE:3400B without its panels. ASMLWhat comes after EUV?The answer is - EUV. So far, EUV optics have reached an NA of 0.33. The next generation (ASML announced the machine as NXE Next) will have an NA of 0.55, enabling a resolution of less than 8 nm.

It comprises larger optics, which explains the large and increased efforts at ZEISS SMT. Zeiss has already started production this year.As a result of these combined efforts, it is clear that the technology is driven to its physical limits, enabling specifications that were hitherto not imaginable. For example, the wafers inside the lithography system are hold on special glass plates (so-called wafer clamps). They move at accelerations up to 3g, keeping the wafer in place with precision down to a nanometer. At the same time, the wafer is illuminated by EUV light at a heat load of 30 kW/m 2 without losing its precise location.Although a number of technical problems are still under discussion, the market seems very confident that EUV lithography will offer a substantial benefit for the semiconductor industry for the foreseeable future.What comes after high-NA EUV? So far, there seems to be no serious answer yet.

Complexity Of Lithography Tools For Sale

On the one hand, several research groups are preparing for shorter wavelengths. They worked on reflective coatings (at IOF) and plasma sources (at ILT) for a 6.7 nm wavelength. Alternative methods of nanopatterning such as stamping or e-beam lithography are evolving. Was an attempt to discuss their further development.But if we look at this development from a distance, it seems that the complexity of lithographic technology has reached its viable maximum.

Complexity Of Lithography Tools And Accessories

What ASML and its allies currently build in their high-tech cathedrals showcases the largest and most advanced technological systems of our time. While this is stunning evidence of scientific and engineering mastery, it leaves the impression that further substantial progress will require a completely different approach to satisfy increased data storage and processing requirements.